FA-I

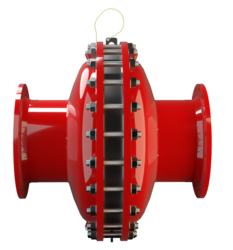

In-Line Deflagration Flame Arrester concentric design, bidirectional

- optimized flow capacity

- different series allow increase of FLAMEFILTER® size for given flange connection resulting in lower pressure drop across the device

- option for integrated cleaning nozzles can be provided

- modular flame arrester unit enables each individual FLAMEFILTER® to be replaced and cleaned

- bi-directional flame transmission proof design

- protects with deflagrations for explosion groups IIA and IIB3 (NEC groups D and C)

- design available for elevated operating temperatures and pressures

- available sizes from DN 50 / 2” to DN 1000 / 40”

- lowest pressure drop results in low operating and lifecycle costs

- modular design reduces spare parts cost

- use of stabilized FLAMEFILTER® discs is possible

- use of PROTEGO® flame arrester unit in unique maintenance friendly design reduces service cost

Function and Description

In the development of the PROTEGO® FA-I in-line deflagration flame arrester, special effort was made to optimize the fluid dynamic flow characteristics. For a given flange connection size of the flame arrester, the FLAMEFILTER® size can be chosen for the most adequate flow capacity. When installing the deflagration flame arrester, make sure that the distance between potential ignition sources and location of the installed device does not exceed the L/D ratio (pipe length/pipe diameter) for which the device was tested (see table 4).

The deflagration flame arrester is symmetrical and offers bidirectional flame transmission protection. The device essentially consists of two housing parts (1) and the PROTEGO® flame arrester unit (2) in the center. The PROTEGO® flame arrester unit is modular and consists of several FLAMEFILTER® discs (3) and spacers firmly held in a FLAMEFILTER® casing. The number of FLAMEFILTER® discs and their gap size depends on the arrester´s intended use.

Specifying the operating conditions, such as the temperature, pressure, explosion group, and the composition of the fluid, enables PROTEGO® to select the best deflagration flame arrester for your application. The PROTEGO® FA-I series of deflagration flame arresters is available for substances of explosion groups IIA and IIB3 (NEC groups D and C (MESG ≥ 0.65 mm)).

The standard design can be used with an operating temperature of up to +60°C / 140°F and an absolute operating pressure up to 1.1 bar / 15.9 psi. Devices with special approvals for higher pressures (see table 3) and higher temperatures are available upon request.

EU conformity according to the currently valid ATEX directive. Approvals according to other national/international regulations on request.

Dimensions

To select nominal width/nominal size (NG/DN) - combination, please use the flow capacity charts on the following pages. Additional nominal width/nominal size (NG/DN) - combinations for improved flow capacity upon request

| standard | |||||||||||||

| NG | 150 / 6" | 150 / 6" | 200 / 8" | 300 / 12" | 400 / 16" | 500 / 20" | 600 / 24" | 800 / 32" | 1000 / 40" | 1200 / 48" | 1400 / 56" | 1600 / 64 | |

| DN | ≤50 / 2" | 80 / 3" | ≤100 / 4" | ≤150 / 6" | ≤200 / 8" | ≤250 / 10" | ≤300 / 12" | ≤400 / 16" | ≤ 00 / 20" | ≤600 / 24" | ≤800 / 32" | ≤800 / 32" | |

| a | 285 / 11.22 | 285 / 11.22 | 340 / 13.39 | 445 / 17.52 | 565 / 22.24 | 670 / 26.38 | 780 / 30.71 | 975 / 38.39 | 1175 / 46.26 | 1405 / 55.31 | 1630 / 64.17 | 1830 / 72.05 | |

| Expl. Gr. | IIA b* | 364 / 14.33 | 364 / 14.33 | 452 / 17.79 | 584 / 22.99 | 638 / 25.12 | 688 / 27.09 | 800 / 31.50 | 900 / 35.43 | 1000 / 39.37 | 1100 / 43.31 | 1350 / 53.15 | 1450 / 57.09 |

| IIB3 b* | 364 / 14.33 | 364 / 14.33 | 464 / 18.27 | 596 / 23.46 | 650 / 25.59 | 700 / 31.50 | 800 / 31.50 | 900 / 35.43 | 1000 / 39.37 | 1100 / 43.31 | 1350 / 53.15 | 1450 / 57.09 | |

| c | 500 / 19.69 | 500 / 19.69 | 520 / 20.47 | 570 / 22.44 | 620 / 24.41 | 670 / 26.38 | 700 / 31.50 | 900 / 35.43 | 1000 / 39.37 | 1100 / 43.31 | 1350 / 53.15 | 1450 / 57.09 |

Material selection for housing

| Design | A | B | C |

| Housing | Steel | Stainless Steel | Hastelloy |

| Gasket | PTFE | PTFE | PTFE |

| Flame arrester unit | A, B | C | D |

Material combinations of flame arrester unit

| Design | A | C | D |

| FLAMEFILTER® cage | Steel | Stainless Steel | Hastelloy |

| FLAMEFILTER®* | Stainless Steel | Stainless Steel | Hastelloy |

| Spacers | Stainless Steel | Stainless Steel | Hastelloy |

Selection of explosion group

| MESG | Expl. Gr. (IEC / CEN) | Gas Group (NEC) |

| > 0,90 mm | IIA | D |

| ≥ 0,65 mm | IIB3 | C |

Selection of max. operating pressure

| Expl. Gr. | NG | 150 / 6'' | 150 / 6'' | 200 / 8'' | 300 / 12'' | 400 / 16'' | 500 / 20'' | 600 / 24'' | 800 / 32'' | 1000 / 40'' | 1200 / 48'' | 1400 / 56' | 1600 / 64'' |

| DN | 50 / 1" | 80 / 3" | 100 / 4" | 150 / 6" | 200 / 8" | 250 / 10" | 300 / 12" | 400 / 16" | 500 / 20" | 600 / 24" | 800 / 32" | 800 / 32" | |

| IIA | Pmax | 1,8 / 26.1 | 1,8 / 26.1 | 1,5 / 21.7 | 1,5 / 21.7 | 1,5 / 21.7 | 1,5 / 21.7 | 1,5 / 21.7 | 1,4 / 20.3 | 1,3 / 18.8 | 1,3 / 18.8 | 1,2 / 17.4 | 1,1 / 15.9 |

| IIB3 | Pmax | 1,2 / 17.4 | 1,2 / 17.4 | 1,2 / 17.4 | 1,2 / 17.4 | 1,2 / 17.4 | 1,2 / 17.4 | 1,2 / 17.4 | 1,2 / 17.4 | 1,2 / 17.4 | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 |

Max. allowable L/D-ratio

| standard | NG | 150 / 6" | 150 / 6" | 200 / 8'' | 300 / 12'' | 400 / 16'' | 500 / 20'' | 600 / 24'' | 800 / 32" | 1000 / 40'' | 1200 / 48'' | 1400 / 56'' | 1600 / 64'' |

| DN | 50 / 1" | 80 / 3" | 100 / 4" | 150 / 6" | 200 / 8" | 250 / 10" | 300 / | 400 / 16" | 500 / 20" | 600 / 24" | 800 / 32" | 800 / 32" | |

| IIA | (L / D)max | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| IIA | Pmax | 1,2 / 17.4 | 1,2 / 17.4 | 1,2 / 17.4 | 1,2 / 17.4 | 1,2 / 17.4 | 1,2 / 17.4 | 1,2 / 17.4 | 1,2 / 17.4 | 1,3 / 18.8 | 1,3 / 18.8 | 1,2 / 17.4 | 1,1 / 15.9 |

| IIA | Designation | - | - | - | - | - | - | - | - | - | - | - | |

| IIB3 | (L / D)max | 50 | 50 | 40 | 40 | 35 | 35 | 35 | 30 | 30 | 30 | 25 | 25 |

| IIB3 | Pmax | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 |

| IIB3 | Designation | - | - | X6 | X6 | X7 | X7 | X7 | X8 | X8 | X8 | X9 | X9 |

Specification of max. operating temperature

| ≤ 60°C / 140°F | Tmaximum allowable operating temperature in °C |

| - | Designation |

Flange connection type

| EN 1092-1; Form B1 |

| ASME B16.5 CL 150 R.F. |

Design Types and Specifications

There are three different designs:

Basic in-line deflagration flame arrester | FA-I - – |

In-line deflagration flame arrester with integrated temperature sensor* as additional protection against short-time burning from one side | FA-I - T |

In-line deflagration flame arrester with two integrated temperature sensors* for additional protection against short-time burning from both sides | FA-I - TB |

Additional special devices available upon request

*Resistance thermometer for device group II, category (1) 2 (GII cat. (1) 2)

Flow Capacity Chart

The flow capacity charts have been determined with a calibrated and TÜV certified flow capacity test rig. Volume flow V in (m³/h) and CFH refer to the standard reference conditions of air ISO 6358 (20°C, 1bar). For conversion to other densities and temperatures refer to Sec. 1: “Technical Fundamentals”.