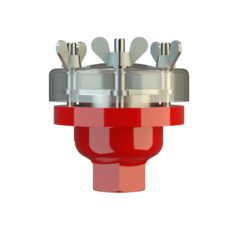

EB-Z

Deflagration Flame Arrester, endurance burning proof, End-of-Line

- protection against atmospheric deflagration and endurance burning of pure hydrocarbons

- weather hood protects against environmental impact (i.e. weather, bird nests, etc.)

- modular design allows replacement of single FLAMEFILTER®

- easy maintenance

- modular design results in low spare part costs

- low operating and lifecycle cost

- cost effective protection for small vessels and process engineering apparatus

Function and Description

The PROTEGO® EB-Z end-of-line deflagration flame arrester has been successfully used to protect small vessels and process engineering apparatus which are not pressurized. The device provides protection against flame transmission through atmospheric deflagration and stabilized flames which can burn for very long time on the flame arrester element surface, so called endurance burning. Main application area is on in- and outbreathing vent lines, with the goal to prevent flame transmission caused by endurance burning or atmospheric deflagration from propagating into the vessel or plant.

The PROTEGO® EB-Z consists of a housing (1), a weather hood (2) and the FLAMEFILTER® (3). The weather hood is made out of acrylic glass, which will melt when impacted by flames and allow heat to dissipate to the environment. The PROTEGO® EB-Z serie end-of-line deflagration flame arrester is available for substances of explosion group IIA (NEC group D MESG > 0.90 mm)

The standard design can be used for operating temperatures up to +60°C / 140°F.

EU conformity according to the currently valid ATEX directive. Approvals according to other national/international regulations on request.

Dimensions

To select the nominal size (DN), please use the flow capacity chart

| DN/ G, NPT | 15 / ½“ | 20 / ¾"<//th> | 25 / 1“ | 32 / 1¼““ |

| a | 87 | 87 | 114 | 114 |

| b | 93 | 93 | 98 | 98 |

| b* | 123 | 123 | 123 | 123 |

| SW | 32 | 32 | 50 | 50 |

Material selection

| Design | B |

| Housing | Stainless Steel |

| Weather Hood | Acrylic glass |

| FLAMEFILTER® | Stainless Steel |

Selection of explosion group

| MESG | Expl. Gr. (IEC / CEN) | Gas Group (NEC) |

| > 0,90 mm | IIA | D |

Type of connection

| Pipe thread DIN ISO 228-1 |

| EN 1092-1; Form B1 |

| ASME B16.5 CL 150 R.F. |

End-of-line deflagration flame arrester, basic design | EB-Z |

Special designs available on request

Flow Capacity Chart

The flow capacity charts have been determined with a calibrated and TÜV certified flow capacity test rig. Volume flow V in (m³/h) and CFH refer to the standard reference conditions of air ISO 6358 (20°C, 1bar). For conversion to other densities and temperatures refer to Sec. 1: “Technical Fundamentals”.