Function and Description

The E/KS vent cap allows vessels which are not pressurize to vent. The vent cap is made out of plastic and is the best solution in applications with aggressive media. This E/KS vent cap prevents rain and dirt from entering the vent line. The device is not flame transmission proof. It is often used in combination with detonation flame arresters, when those are used in vent lines, installed at a position which creates a long run up distance from the end of the vent line to prevent endurance burning. The E/KS vent cap will then be installed at the end of that vent line to prevent particles or rain from entering the line.

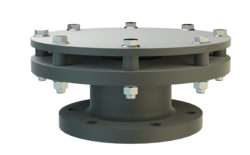

The vent caps main components are a housing (1), a weather hood (2) and spacers (3).

Dimensions

To select the nominal size (DN), please use the flow capacity charts on the following pages

| DN | 50 / 2" | 80 / 3" | 100 / 4" | 150 / 6" | 200 / 8" |

| a | 135 / 5.31 | 140 / 5.51 | 145 / 5.71 | 195 / 7.68 | 200 / 7.87 |

| b | 170 / 6.69 | 230 / 9.06 | 300 / 11.81 | 375 / 14.76 | 450 / 17.72 |

Material selection

| Design | A | B | C |

| Housing | PE | PP | PVDF |

| Weather hood | PE | PP | PVDF |

Flange connection type

| EN 1092-1; Form B1 |

| ASME B16.5 CL 150 R.F. |

Design Types and Specifications

Following designs are available:

Vent cap, basic design | E/KS |

Special designs available on request

Flow Capacity Chart

The flow capacity charts have been determined with a calibrated and TÜV certified flow capacity test rig. Volume flow V in (m³/h) and CFH refer to the standard reference conditions of air ISO 6358 (20°C, 1bar). For conversion to other densities and temperatures refer to Sec. 1: “Technical Fundamentals”.