DA-SB-EO-P1,1

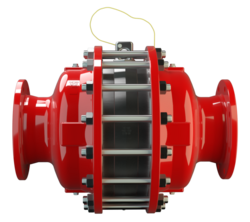

In-Line Detonation Flame Arrester for stable detonations and deflagrations in a straight through design with shock tube, bidirectional

- Worldwide first flame arresting unit for Ethylene oxide, which has been tested and approved with Ethylene oxide/air-mixtures

- Provides protection from flame transmission with Ethylene oxide/air-mixtures

- Optimized performance from the patented Shock Wave Guide Tube Effect (SWGTE)

- Less number of FLAMEFILTER® from the use of the patented shock tube

- The modular design enables individual FLAMEFILTER® to be replaced

- Minimum pressure loss and associated low operating and life-cycle costs

- Cost efficient spare parts

- Service-friendly design

- Bidirectional operation as well as any direction of flow and installation position

Function and Description

The in-line detonation flame arresters type PROTEGO® DA-SB-EO are the newest generation of flame arresters. Based on flow and explosion dynamic calculations as well as decades of field tests, a product line was developed that offers minimum pressure losses with maximum safety. The flame arrester uses the Shock Wave Guide Tube Effect (SWGTE) to separate the flame front and shock wave. The result is an in-line detonation arrester without a classic shock absorber, which minimizes the use of FLAMEFILTER® discs.

The devices are symmetrical and offer bi-directional flame arresting for deflagrations and stable detonations for Ethylene oxide/air-mixtures. The arrester essentially consists of two housing parts with an integrated shock tube (1) and the PROTEGO® flame arrester unit (2) in the center. The PROTEGO® flame arrester unit is modular and consists of several FLAMEFILTER® discs (3) and spacers firmly held in a FLAMEFILTER® casing.

The standard design can be used with an operating temperature of up to +60°C / 140°F and an absolute operating pressure up to 1.1 bar / 15.9 psi.

EU conformity according to the currently valid ATEX directive.

Dimensions

To select nominal width/nominal size (NG/DN) - combination, please use the flow capacity charts on the following pages

| NG | 150 / 6“ | 150 / 6“ | 200 / 8“ | 300 / 12“ | 400 / 16“ |

| DN | ≤50 / 2" | 65, 80 / 2½", 3" | ≤100 / 4" | ≤150 / 6" | ≤200 / 8" |

| a | 285 / 11.22 | 285 / 11.22 | 340 / 13.39 | 445 / 17.52 | 565 / 22.24 |

| b | 400 / 15.75 | 400 / 15.75 | 500 / 19.69 | 638 / 25.12 | 700 / 27.56 |

| c | 500 / 19.69 | 500 / 19.69 | 520 / 20.47 | 570 / 22.44 | 620 / 24.41 |

Material selection for housing

| Design | A | B | C |

| Housing | Steel | Stainless Steel | Hastelloy |

| Heating jacket (DA-SB-(T)-H-...EO) | Steel | Stainless Steel | Stainless Steel |

| Gasket | PTFE | PTFE | PTFE |

| Flame arrester unit | A, B | B, C, D | D |

Material combinations of flame arrester unit

| Design | A | B | C | D |

| FLAMEFILTER® cage | Steel | Stainless Steel | Stainless Steel | Hastelloy |

| FLAMEFILTER®* | Stainless Steel | Stainless Steel | Hastelloy | Hastelloy |

| Spacer | Stainless Steel | Stainless Steel | Hastelloy | Hastelloy |

Selection of explosion group

| MESG | Expl. Gr. (IEC / CEN) | Gas Group (NEC) |

| ≥ 0,59 mm | EO | EO |

Selection of max. operating pressure

| DN | ≤50 / 2" | 65, 80 / 2½", 3" | ≤100 / 4" | ≤150 / 6" | ≤200 / 8" |

| NG | 150 / 6'' | 150 / 6'' | 200 / 8'' | 300 / 12'' | 400 / 16'' |

| Pmax | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 |

*capacity charts upon request

Specification of max. operating temperature

| ≤ 60°C / 140°F | Tmaximum allowable operating temperature in °C |

Flange connection type

| EN 1092-1; Form B1 |

| ASME B16.5 CL 150 R.F. |

Design Types and Specifications

There are four different designs available:

Basic design of the detonation arrester | DA-SB - – - EO |

In-line detonation flame arrester with integrated temperature sensor* as additional protection against short time burning of one side | DA-SB- T - EO |

Detonation arrester with two integrated temperature sensors* as additional protection against short time burning from both sides | DA-SB- TB - EO |

In-line detonation flame arrester with heating jacket | DA-SB- H - EO |

Additional special arresters upon request

*Resistance thermometer for device group II, category (1) 2 (GII cat. (1) 2)

Flow Capacity Chart

The flow capacity charts have been determined with a calibrated and TÜV certified flow capacity test rig. Volume flow V in (m³/h) and CFH refer to the standard reference conditions of air ISO 6358 (20°C, 1bar). For conversion to other densities and temperatures refer to Sec. 1: “Technical Fundamentals”.