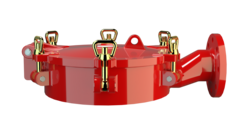

BR/TS-80-IIB3

Detonation Flame Arrester for tank ships and containers

- meets all ADN* requirements

- flat design

- the emergency venting with the flexibly mounted flame arrester enables use even in bad weather conditions as well as with contaminated products

- extraordinarily easy to service

- the design of the PROTEGO® flame arrester unit enables individual FLAMEFILTER® discs to be replaced

- we offer support in calculating loading and unloading rates

- applicable for nearly all flammable liquids

- may be used as maintenance and cleaning hatch

- cost efficient spare parts

Function and Description

The PROTEGO® BR/TS-80-IIB3 detonation flame arrester was developed for protecting tankships but can also be used for containers. These devices are especially used on tank ships operating on inland waterways or coastal shipping. The device is installed on the tank or a pipe section connected to the tank with a nominal size of 250 mm / 10" and connected to the vapour balancing line (DN 80 / 3"). The individual tanks connected via the vapour balancing line are technically decoupled by the detonation arresters and protected.

The device protects against unidirectional detonation. In particular, the arrester consists of a shock absorber (1) and the PROTEGO® flame arrester unit (2). The PROTEGO® flame arrester unit consists of several FLAMEFILTER® discs (3) and spacers fi rmly held in a FLAMEFILTER® cage (4). It is moveable and can be folded to the side for maintenance. The primary goal of this design is to enable the tank to be vented or supplied with air in an emergency when ice or crystallizing products clog the FLAMEFILTER®. The PROTEGO® BR/TS flame arrester is available for explosion groups IIA to IIB3 (NEC group D and C MESG ≥ 0.65 mm).

The standard design is approved up to an operating temperature of +60°C / 140°F and an operating pressure up to 1.55 bar / 22.47 psi (absolute), and it meets all the conditions of the ADN* for hazardous goods transport on European Inland Waterways.

EU conformity according to the currently valid ATEX directive. Approvals according to other national/international regulations on request.

Material selection for housing

| Design | A | B | |

| Housing | Steel | Stainless Steel | |

| Cover | Steel | Stainless Steel | |

| Gasket | Tankatite | Tankatite | |

| Flame arrester unit | A | A |

Material selection for flame arrester unit

| Design | A |

| FLAMEFILTER® cage | Stainless Steel |

| FLAMEFILTER® | Stainless Steel |

| Spacer | Stainless Steel |

Flange connection type

| EN 1092-1; Form B1 |

| ASME B16.5 CL 150 R.F. |

Flow Capacity Chart

The flow capacity charts have been determined with a calibrated and TÜV certified flow capacity test rig. Volume flow V in (m³/h) and CFH refer to the standard reference conditions of air ISO 6358 (20°C, 1bar). For conversion to other densities and temperatures refer to Sec. 1: “Technical Fundamentals”.