PROTEGO® Breather Valves

Reduction of Vapour Emissions & Safe Plant Operation

In closed containers or tanks containing liquids, effectively managing pressure is crucial. To ensure secure operations, it is vital to have a dependable mechanism for releasing accumulated pressure and compensating for vacuum conditions. PROTEGO® addresses this requirement precisely through our Overpressure and Vacuum Relief Valves. These valves, equipped with weight-loaded or spring-loaded valve pallets, play a crucial role in maintaining optimal pressure levels within tanks.

Whether dealing with overpressure or vacuum situations during processes such as loading, unloading, steam cleaning, or due to thermal effects, PROTEGO® valves offer a robust solution. Our valves, meticulously designed, function as pressure relief valves, vacuum relief valves, or combined pressure and vacuum relief valves.

Industries such as oil and gas, petroleum, chemical, pharmaceutical, and bio-energy depend on PROTEGO® valves to ensure the safety and efficiency of their operations. The innovative design and superior performance of our valves make them the trusted choice for a wide range of applications in the industrial landscape.

Find the perfect valve for your application

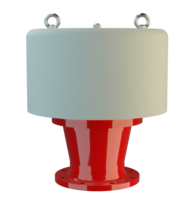

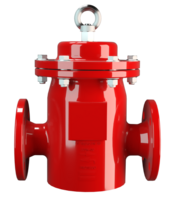

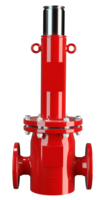

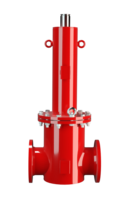

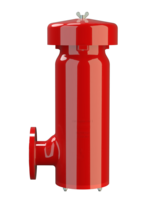

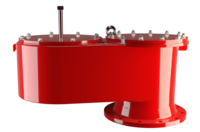

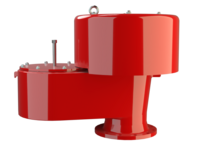

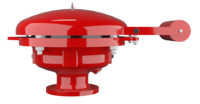

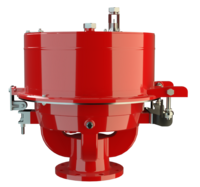

Pressure / Vacuum Relief Valves

without integrated Flame Arresters

PROTEGO® pressure/vacuum relief valves are used as in-breathing and out-breathing valves, pressure relief valves, conservation valves, and for simple control and venting of tanks and equipment when an unallowable vacuum or pressure is exceeded. PROTEGO® valves are available as pressure relief valves, vacuum relief valves, or as combined pressure/vacuum relief valves.

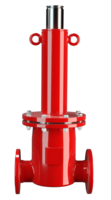

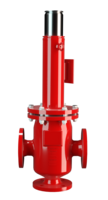

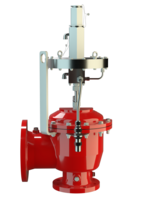

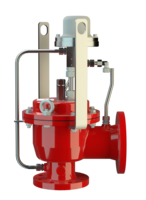

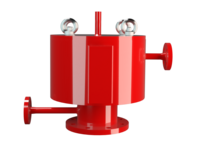

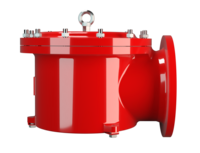

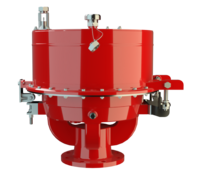

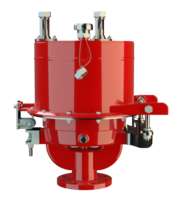

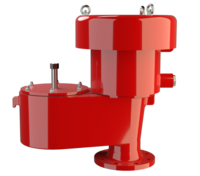

Pressure / Vacuum Relief Valves

with integrated Flame Arrester

These valves are used to protect plant components (e.g. tanks, pipelines) from exceeding maximum allowable operating pressures and vacuum. They offer additional protection against atmospheric deflagration, and some valves also protect against endurance burning.

Zero Emissions

PROTEGO® Valves help to reach Net Zero for a Sustainable Future

Due to the highly developed manufacturing technology of PROTEGO® valves the tank pressure is maintained up to set pressure with a tightness that is far superior to the conventional standard. According to the PROTEGO® Standard PS-001 leak rates are measured at 90% of the set pressure. This testing ensures PROTEGO® Valves exceed the most stringent leakage rate requirements of EPA, API2000 and EN ISO 28300.

The extreme tightness of PROTEGO® Valves guarantees Zero Emission at Tank Operating Pressure.

Product losses are minimized and emissions are reduced

To meet the goal of emission reduction, PROTEGO® full lift vents utilize 10% overpressure technology. This technology provides very short opening and closing pressure ranges. The vent only requires 10% overpressure above the set pressure to reach full performance. The tank pressure is maintained up to just below the maximum permissible tank pressure.

PROTEGO® 10% full-lift technology vents are a major benefit to emission reduction and to safe process plant operation.

Trusted by leaders worldwide

"PROTEGO® Valves have an excellent tightness. The leakage of the valve is much lower than the requirement of local environmental protection bureaus. We are very satisfied with the PROTEGO® products."

one of the world's largest petroleum and petrochemical companies