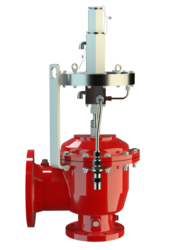

PM-HF

Pressure/Vacuum Relief Valve Pilot-operated diaphragm valve

- controlled by corrosion-resistant pilot valve

- small amount fl uid stored in the tank released into the atmosphere by the pilot when the valve opens

- max. 10% Technology for minimum pressure increase until full lift

- seals extremely tight; hence, least possible product losses and reduced impact on the environment

- set-to-operate pressure close to the opening pressure; hence, best possible pressure management of the system.

- control diaphragm of the main valve shielded from low temperatures - Long service life

- high flow capacity

- suited for use in hazardous areas

- Field-Test-Connection on request

- Field-Test-Kit on request

Function and Description

The PROTEGO® Type PM-HF pilot-controlled diaphragm valve is a highly developed valve for pressure and vacuum relief. Primarily used as a device for outbreathing in tanks, vessels, and process engineering equipment it also offers reliable protection from vacuum and overpressure. It prevents intake of air and unacceptable product vapor loss up to and until the set-to-operate pressure is reached. The valve can be used as an inbreathing device as well. In such an application, the main valve is directly controlled when exposed to a vacuum, i.e. it functions as a weight-loaded diaphragm valve.

The main valve is controlled by a pilot valve. The latter in turn is controlled by the tank pressure. A small amount fluid stored in the tank released into the atmosphere by the pilot when the valve opens. The set-to-operate pressure is adjusted on the pilot valve by increasing or decreasing (as appropriate) the tension of a spring.

As the working pressure rises, the closing force acting on the main valve increases, i.e. the valve's tight-sealing is enhanced until the set-to-operate pressure is reached, thus preventing leakage. Once the valve has commenced to lift it opens fully within a 10% pressure rise or the opening pressure difference and the nominal volumetric fl ow is discharged through a fully open valve. If and when this level is exceeded the pressure increase will follow the performance curve (Δp/V.curve). From set pressure to full capacity (fully open valve) the pressure increase is 100% in case of vacuum venting/inbreathing function.

Due to the sophisticated manufacturing technology, the tank pressure is maintained up to the set-to-operate pressure, with seal-tight requirements far above common standards being met. This feature is achieved through valve seats made of high-grade stainless steel with precisely ground valve pallets. Once the excess pressure is relieved or pressure below atmospheric balanced out, the valve reseats and seals tight again.

Dimensions

To select the nominal size (DN), use the flow capacity charts on the following pages

| DN1 | 80 / 3" | 100 / 4" | 150 / 6" | 200 / 8" | 250 / 10" | 300 / 12" | 300 / 12" |

| DN2 | 100 / 4" | 150 / 6" | 200 / 8" | 250 / 10" | 300 / 12" | 350 / 14" | 400 / 16" |

| a | 225 / 8.86 | 250 / 9.87 | 325 / 12.80 | 375 / 14.76 | 450 / 17.72 | 500 / 19.69 | 500 / 19.69 |

| b | 150 / 5.91 | 175 / 6.89 | 225 / 8.86 | 250 / 9.84 | 270 / 10.63 | 300 / 12.81 | 325 / 12.80 |

| c | 275 / 10.83 | 330 / 12.99 | 445 / 17.52 | 550 / 21.65 | 665 / 26.18 | 785 / 30.91 | 785 / 30.91 |

| d | 376 / 14.80 | 429 / 16.89 | 536 / 21.10 | 607 / 23.90 | 678 / 26.69 | 796 / 31.34 | 846 / 33.31 |

| e | 763 / 30.04 | 770 / 30.31 | 923 / 36.34 | 977 / 38.46 | 1052 / 41.42 | 1173 / 46.18 | 1223 / 48.15 |

| f | 35 / 1.38 | 40 / 1.57 | 40 / 1.57 | 50 / 1.97 | 50 / 1.97 | 50 / 1.97 | 50 / 1.97 |

Material selection for housing

| Design | A | B |

| Housing | Aluminium | Stainless Steel |

| Valve seat | Stainless Steel | Stainless Steel |

| Sealing | KL-C-4106 | KL-C-4106 |

| Main diaphragm protection | Stainless Steel | Stainless Steel |

| Pilot lines | Stainless Steel | Stainless Steel |

| Pilot housing | Aluminium | Aluminium / Stainless Steel |

| Pilot diaphragm | FEP | FEP |

Coefficient of Discharge

| DN1 | 80 / 3" | 100 / 4" | 150 / 6" | 200 / 8" | 250 / 10" | 300 / 12" | 300 / 12" |

| DN2 | 100 / 4" | 150 / 6" | 200 / 8" | 250 / 10" | 300 / 12" | 350 / 14" | 400 / 16" |

| do | 81 / 3.19 | 107 / 4.21 | 160 / 6.30 | 208 / 8.19 | 260 / 10.24 | 310 / 12.20 | 310 / 12.20 |

| K | 0,68 | 0,68 | 0,63 | 0,59 | 0,58 | 0,54 | 0,61 |

DN2 = Size Outlet

d0 = Orifice Diameter (mm / inches)

K = Coefficient of Discharge

Flange connection type

| EN 1092-1; Form B1 |

| ASME B16.5 CL 150 R.F. |

Design Types and Specifications

Following designs are available:

Basic design of pressure/vacuum relief valve with a control pilot valve | PM-HF |

Additional special devices available upon request

*It is recommended thet an external control line be provided with direct connection to the tank

Settings

| Pressure: | +10 mbar | +1034 mbar | |

| +4 inch W.C. | +413.6 inch W.C. | ||

| Vacuum: | -3.0 mbar | -7 mbar | |

| -1.2 inch W.C. | -2.8 inch W.C. | ||

| -2.2 mbar | -7 mbar | ||

| -0.88 inch W.C. | -2.8 inch W.C. |

Flow Capacity Chart

The flow capacity charts have been determined with a calibrated and TÜV certified flow capacity test rig. Volume flow V in (m³/h) and CFH refer to the standard reference conditions of air ISO 6358 (20°C, 1bar). For conversion to other densities and temperatures refer to Sec. 1: “Technical Fundamentals”.