DA-SB-PTFE

In-Line Detonation Flame Arrester for stable detonations and deflagrations in a straight through design with shock absorber, bidirectional

- build up of adhesive materials is prevented by the smooth surfaces

- application especially for corrosive and polymerising media

- minimum number of FLAMEFILTER® discs due to the effective shock absorber

- different series allow increase of FLAMEFILTER® size for given flange connection resulting in lower pressure drop across the device

- service-friendly design

- the modular design enables each individual FLAMEFILTER® to be replaced

- bidirectional operation as well as any direction of flow and installation position

- installation of temperature sensors is possible

- less soiling of the device lowers service, operating and life-cycle cost

- minimum pressure loss and associated low operating and life-cycle cost

Function and Description

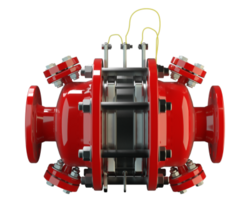

The in-line detonation flame arresters type PROTEGO® DA-SB-PTFE are the latest generation of flame arresters and are distinguished by its unique resistance to adhesive and corrosive media. The use of fluoroplastics as a high-tech housing coating and as solid material for the flame arrester element is unique throughout the world.

The speed of incoming detonations is highly reduced by the effective shock absorber (1) and result in an equal pressure distribution across the FLAMEFILTER® surface. This improves the flame extinction in the narrow gaps of the original PTFEFLAMEFILTER® (3).

The devices are symmetrical and offer bidirectional flame arresting for deflagrations and stable detonations. The arrester essentially consists of two coated housing parts (4), two coated shock absorbers and the PROTEGO® flame arrester unit (2) in the center. The PROTEGO® flame arrester unit is modular and consists of several FLAMEFILTER® discs and spacers firmly held in a FLAMEFILTER® cage. The number of FLAMEFILTER® discs and their gap size depends on the arrester‘s conditions of use.

The detonation arrester PROTEGO® DA-SB-PTFE can be used for explosion group IIA (NFPA group D). The standard design is approved at an operating temperature up to +60°C / 140°F. The maximum allowable operating pressure depends on nominal diameter (DN) and nominal size (NG) and amounts to a maximum of 2.4 bar / 34.8 psi absolute (for DN50 / 2” see table 3).

EU conformity according to the currently valid ATEX directive. Approvals according to other national/international regulations on request.

Dimensions

To select nominal width/nominal size (NG/DN) - combination, please use the flow capacity chart on the following pages

| NG | 150 / 6" | 150 / 6" | 200 / 8" | 300 / 12" |

| DN | 50 / 2" | 80 / 3" | 80 / 3" | 100 / 4" |

| a | 287 / 11.30 | 287 / 11.30 | 342 / 13.46 | 447 / 17.60 |

| b | 407 / 15.75 | 407 / 15.75 | 497 / 19.57 | 645 / 25.39 |

| c | 400 / 15.75 | 400 / 15.75 | 530 / 20.87 | 530 / 20.87 |

Material for housing

| Design | A |

| Housing | Steel with an ECTFE coating |

| Shock absorber | Steel with an ECTFE coating |

| Gasket | PTFE |

| Flame arrester unit | A, B, C |

Material combinations of flame arrester unit

| Design | A | B | C |

| FLAMEFILTER® cage | Steel with an ECTFE coating | Hastelloy | Stainless Steel |

| Spider rings | Steel with an ECTFE coating | Hastelloy | Stainless Steel |

| FLAMEFILTER®* | PTFE* | PTFE* | PTFE* |

| Spacer | PEEK / ETFE / FEP | PEEK / ETFE / FEP | PEEK / ETFE / FEP |

Selection of explosion group

| MESG | Expl. Gr. (IEC / CEN) | Gas Group (NEC) |

| > 0,90 mm | IIA | D |

Selection of max. operating pressure

| NG | 150 / 6" | 150 / 6" | 200 / 8" | 300 / 12" |

| DN | 50 / 2" | 80 / 3" | 80 / 3" | 100 / 4" |

| Pmax | 2,4 / 34.8 | 1,1 / 15.9 | 1,2 / 17.4 | 1,2 / 17.4 |

Specification of max. operating temperature

| ≤ 60°C / 140°F | Tmaximum allowable operating temperature in °C |

| - | Designation |

Flange connection type

| EN 1092-1; Form B1 |

| ASME B16.5 CL 150 R.F. |

Design Types and Specifications

There are three different designs available:

Basic in-line detonation flame arrester | DA-SB-PTFE - – |

In-line detonation flame arrester with integrated temperature sensor* as additional protection against short time burning of from side | DA-SB-PTFE - T |

In-line detonation flame with two integrated temperature sensors* as additional protection against short time burning from both sides | DA-SB-PTFE - TB |

Additional special flame arresters upon request

*Resistance thermometer for device group II, category (1) 2 (GII cat. (1) 2)

Flow Capacity Chart

The flow capacity charts have been determined with a calibrated and TÜV certified flow capacity test rig. Volume flow V in (m³/h) and CFH refer to the standard reference conditions of air ISO 6358 (20°C, 1bar). For conversion to other densities and temperatures refer to Sec. 1: “Technical Fundamentals”.