Function and Description

PROTEGO® lift-actuated vent valves type AL/DK provide automatic venting of floating roof tanks when the floating roof is lowered onto its supports and the tank is either drained or refilled. When the floating roof is in its lowest position, the valve is forced to open through lift actuation, which prevents inadmissible vacuum during final draining or inadmissible pressure during refilling.

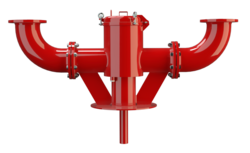

The PROTEGO® AL/DK valve consists of a housing (1) with a sheet metal panel to be welded onto the floating roof, two or four connection nozzles (2) for installation of vent caps, cover (3), lift (4) including valve disc (5), lift pipe (6), and the condensate drain valve (7) which can be designed to be flame transmission proof. The condensate drain is sealed by a flat gasket attached to the valve disk (5). The cover (3) is sealed by a sealing cord (8).

In general the device PROTEGO® AL 200 consists of a housing (1) with sheet-metal panel to be welded on the floating roof as well as the valve seat (2), lift (3) including valve pallet (4) and lift pipe (5). A flat gasket (6) provides sealing.

As the lowest position of the floating roof varies for operation and assembly, specify the dimensions h1 and h2:

h1: Distance between the lower edge of sheet-metal panel (or mounting flange) and the tank bottom in lowest position of floating roof (operating position with an empty tank).

h2: Distance between the floating roof in lifted maintenance position and the height of the floating roof in fully lowered operating position (operating position with an empty tank).

If the floating roof supports are changed from operating position to maintenance position, the lift has to be extended as well. This is done with an adjustable locking pin that is secured with a split pin.

The valve is not flame transmission proof.

Based on a hazard analysis with regard to material selection and function, the valves have no potential ignition sources. As a result, they are not subject to the European Explosion Protection Directive (ATEX) when used in explosive atmospheres.

Dimensions for AL/DK

| NG | 200 / 8" | 200 / 8" | 200 / 8" | 200 / 8" |

| DN | 80 / 3" | 100 / 4" | 150 / 6" | 200 / 8" |

| a | 350 / 13.78 | 350 / 13.78 | 350 / 13.78 | 350 / 13.78 |

| b | 465 / 18.31 | 465 / 18.31 | 465 / 18.31 | 515 / 20.28 |

| c | 870 / 34.25 | 870 / 34.25 | 870 / 34.25 | 870 / 34.25 |

| d | 450 / 17.72 | 450 / 17.72 | 450 / 17.72 | 450 / 17.72 |

| e | 345 / 13.58 | 360 / 14.17 | 385 / 15.16 | 415 / 16.34 |

| f | 460 / 18.11 | 445 / 17.52 | 285 / 11.22 | 370 / 14.57 |

Material

| Housing | Steel |

| Valve guide | Stainless Steel |

| Gasket | FPM |

Data Necessary for Specification

Stored product Tank diameter (m or ft)

Tank height (m or ft)

Support height h1 (operating position with empty tank)

Support height h2 (lifted assembly position)

Maximum allowable tank pressure pT (mbar or inch W.C.)

Pump rate (m³/h or CFH)

Selection and Design

The required quantity and nominal size DN will be defined based on the calculated flow rate from the thermal venting and pumprate in lowest floating roof position (Nm³/h or CFH) and based on the maximum acceptable tank pressure pT (mbar / inch W.C.) according to the flow capacity charts. Special models are available on request.Flow rates and pressure losses of vent caps PROTEGO® BE/HRor PROTEGO® LH/AD have additionally to be taken into account according to the appropriate charts in the relevant data sheetsor operating instructions. Lift-actuated vent valves PROTEGO® AL 200 can be applied incase just venting is required.

Flange connection type

| EN 1092-1; Form B1 | andere Anschlüsse auf Anfrage |

| ASME B16.5 CL 150 R.F. |

Flow Capacity Chart

The flow capacity charts have been determined with a calibrated and TÜV certified flow capacity test rig. Volume flow V in (m³/h) and CFH refer to the standard reference conditions of air ISO 6358 (20°C, 1bar). For conversion to other densities and temperatures refer to Sec. 1: “Technical Fundamentals”.

Lift-actuated vent valves of type PROTEGO® AL/DK can be combined with vent caps type BE/HR which are deflagration proof and resistant against endurance burning. This ensures flame transmission proof ventilation.

If resistance against endurance burning is not required the valves can alternatively be combined with PROTEGO® deflagration proof devices type PROTEGO® LH/AD. The applicable data sheets are available in volume 2 “Deflagration Flame Arresters, end-of-line and Vent Caps”.

PROTEGO® AL 200 for fixed roof storage tanks with internal floating roof.