PM/(D)S

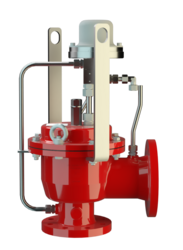

Pressure/Vacuum Relief Valve Pilot-operated diaphragm valve

- high level of safety due to double pilot

- controlled by corrosion-resistant, low-temperature-resistant permanent magnet

- no continuous flow of the tank substance through the pilot valve

- pop-open characteristic from the lowest pressure increase up to full lift

- extreme tightness, resulting in lowest possible product losses and reduced environmental pollution

- set pressure close to opening pressure for optimum pressure maintenance in the system

- high flow capacity

- protection of the main valve control diaphragm from low temperatures – high durability

- can be used in explosion hazardous areas

- designed for use at low temperatures

- automatic condensate drain

Function and Description

The PM/(D)S pilot-operated PROTEGO® diaphragm valve is a highly developed valve for pressure and vacuum relief. It is primarily used as a device for out-breathing in tanks, containers, and process equipment. It provides protection against unallowable overpressure and prevents the intake of air and unallowable product vapor loss up to the set pressure.

The valve can also be used as an in-breathing valve where the main valve is directly controlled when it is exposed to a vacuum, i.e., it functions as a weight-loaded diaphragm valve. It is ideally suitable for both atmospheric conditions and for use in low temperatures.

The main valve is controlled by a pilot valve. The pilot valve is controlled by the tank pressure. The tank substance does not continuously flow through the pilot. The set pressure is adjusted on the pilot valve by a corrosion-resistant and low-temperature resistant permanent magnet.

As the operating pressure increases, the closing force at the main valve also increases; i.e., the valve tightness increases until the set pressure is reached to prevent leakage. After the valve responds, it immediately opens completely without any significant increase in pressure (pop-open characteristic), and the nominal volumetric flow is released through a fully open valve. If this is exceeded, the pressure increase follows the volume flow (Δp/V̇ curve). The tank pressure is maintained up to the set pressure with a tightness that is above the normal standards due to our state-of-the art manufacturing. This feature is ensured by valve seats made of high quality stainless steel with precisely lapped valve pallets. After the overpressure is released or the vacuum is balanced, the valve re-seats and provides a tight seal.

Dimensions

To select the nominal size (DN), use the flow capacity charts on the following pages

| DN1 | 80 / 3" | 100 / 4" | 150 / 6" | 200 / 8" | 250 / 10" | 300 / 12 | 300 / 12" |

| DN2 | 100 / 4" | 150 / 6" | 200 / 8" | 250 / 10" | 300 / 12" | 350 / 14" | 400 |

| a | 225 / 8.86 | 250 / 9.87 | 325 / 12.80 | 375 / 14.76 | 450 / 17.72 | 500 / 19.69 | 500 / 19.69 |

| b | 150 / 5.91 | 175 / 6.89 | 225 / 8.86 | 250 / 9.84 | 270 / 10.63 | 300 / 11.81 | 325 / 12.79 |

| c | 275 / 10.83 | 330 / 12.99 | 445 / 17.52 | 550 / 21.65 | 665 / 26.18 | 785 / 30.91 | 785 / 30.91 |

| d | 370 / 14.57 | 425 / 16.73 | 530 / 20.87 | 605 / 23.82 | 675 / 26.57 | 785 / 30.91 | 835 / 32.87 |

| e | 615 / 24.21 | 685 / 26.97 | 770 / 30.31 | 825 / 32.48 | 935 / 36.81 | 1005 / 39.57 | 1055 / 41.53 |

| f | 35 / 1.38 | 40 / 1.57 | 40 / 1.57 | 50 / 1.97 | 50 / 1.97 | 50 / 1.97 | 50 / 1.97 |

| g | 160 / 6.30 | 195 / 7.68 | 250 / 9.84 | 315 / 12.40 | 370 / 14.57 | 425 / 16.73 | 425 / 16.73 |

Material selection for housing

| Design | A | B |

| Housing | Aluminium | Stainless Steel |

| Valve seat | Stainless Steel | Stainless Steel |

| Sealing | KL-C-4106 | KL-C-4106 |

| Main diaphragm protection | Stainless Steel | Stainless Steel |

| Pilot lines | Stainless Steel | Stainless Steel |

| Pilot housing | Stainless Steel | Stainless Steel |

| Pilot diaphragm | FEP | FEP |

Material selection for valve pallet

| Design | A | B | C |

| Pressure range [mbar] [inch W.C.] | -3,0 up to -4* -1.2 up to -1.6* | -4,0 up to -5,0* -1.6 upm to -2.0* | -5,0 up to -7,0* -2.0 up to -2,8* |

| Valve pallet | Aluminium | Stainless Steel | Stainless Steel |

| Diaphragm | FEP | FEP | FEP |

| Diaphragm pallet | Aluminium | Aluminium | Stainless Steel |

Flange connection type

| EN 1092-1; Form B1 |

| ASME B16.5 CL 150 R.F. |

Design Types and Specifications

The valve is equipped with either a control pilot valve or with one control and emergency pilot valve to ensure optimum operating safety in case of malfunctions or damage.

Two different designs are therefore available:

Basic design of pressure/vacuum relief valve with a control pilot valve | PM/S |

Basic pressure/vacuum relief valve with a control pilot valve and additional emergency pilot valve | PM/DS |

Additional special devices available upon request.

Settings

| Pressure: | +10 mbar | +300 mbar | |

| +4 inch W.C. | +120 inch W.C. | ||

| Vacuum: | -3.0 mbar | -7 mbar | |

| -1.2 inch W.C. | -2.8 inch W.C. |

Flow Capacity Chart

The flow capacity charts have been determined with a calibrated and TÜV certified flow capacity test rig. Volume flow V in (m³/h) and CFH refer to the standard reference conditions of air ISO 6358 (20°C, 1bar). For conversion to other densities and temperatures refer to Sec. 1: “Technical Fundamentals”.